Wear Plate Solutions – Mining & Cement Industrial

BUTECH designed abrasive plates and tubes to withstand the rigors of highly abrasive environments and solve the problem of wear in many industries.

By reducing wear and tear, the life of components is extended, reducing downtime allowing users to focus on production instead of maintenance, and increasing efficiency. Below are some examples of switching to wear-resistant panels in place of more traditional materials.

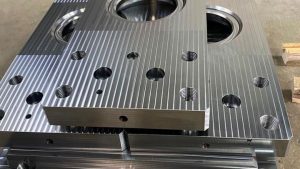

For wear-resistant plates, customers can choose wear-resistant welding or Hardox plates

Clinker cooler plates.

We made the surface of the cooler plate of heat-resistant and wear-resistant steel

Besides abrasion-resistant steel plate products, BUTECH also designs and selects Cast steel product lines as spare replacements for heavy industry.

High manganese steel series

They are wear-resistant materials mainly used in metallurgical, mining, and crushing equipment, including ordinary high manganese steel, changed high manganese steel, ultra-high manganese steel, and treated high manganese steel Strongly processed by multi-component alloy, and high-magnetic aluminum, steel lining plate.

Medium and low alloy steel series

We mainly used these products as lining plates for power plants, coal plants, cement plants, and some mining ball mills, with the characteristics of good adaptability, no deformation, no breakage, and a lifespan twice that of high manganese steel.

The cast iron series has a high chromium content

They mainly used these products in crushing or metallurgical, mining, and cement equipment, suitable for medium-impact casting. With favorable cost performance and sound wear resistance, we divided them into four groups according to service conditions: KmBCr15, KmTBCr20, KmTBCr26, and compound type.